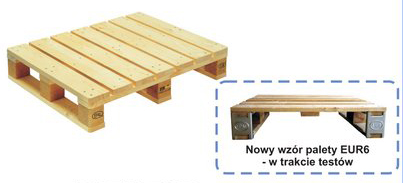

EUR pallet 800x1200 mm

Material: 17 boards made of quality timber, 9 particle or solid wood blocks, 133 nails, manufactured according to the EPAL Technical Regulations.

When stacking laden pallets on top of each other on a hard and smooth surface, ensure that the load on the bottom pallet does not exceed 4,250 kg.

ISPM 15 Standards

Compliance with the ISPM 15 standard is the most essential condition for the unrestricted use of load carriers in the international movement of goods. That is why all EPAL Euro pallets are manufactured according to the stringent specifications of the IPPC and can thus be deployed around the globe. National plant protection agencies provide information on the countries that recognise the IPPC standard.

Material: 13 boards made of quality timber, 9 particle or solid wood blocks, 84 nails, manufactured according to the EPAL Technical Regulations.

When stacking laden pallets on top of each other on a hard and smooth surface, ensure that the load on the bottom pallet does not exceed 4500 kg.

Quality control

Quality is the key requirement for reliable and safe use of EPAL pallets in international companies' supply chains. The open pool of EPAL pallets is the only pool around the globe which undergoes regular independent quality inspections by one of the most renowned inspection companies in the world - Bureau Veritas.

Materials: 13 boards of quality timber, 9 particle or solid wood blocks, 69 nails, manufactured according to the EPAL Technical Regulations.

When stacking laden pallets on top of each other on a hard and smooth surface, ensure that the load on the bottom pallet does not exceed 2000 kg.

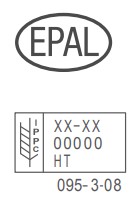

Markings

the acronym “EPAL” in an oval on the left-hand and right-hand corner block (since 08/2013) IPPC marking, country code, registration number of the country's plant protection authority, method of treatment (heat treatment), licence number year, month on the central block.

EPAL control staples

EUR wooden pallet dimensions

| No | Element |

Number |

Dimensions at 22% humidity | ||

|---|---|---|---|---|---|

length |

width |

thickness |

|||

| 1 | Outer deck board |

2 | 1200 | 145 | 22 |

| 2 | Centre deck board |

1 | 1200 | 145 | 22 |

| 3 | In-between deck board |

2 | 1200 | 100 | 22 |

| 4 | Stringer board |

3 | 800 | 145 | 22 |

| 5 | Outer bottom board |

2 | 1200 | 100 | 22 |

| 6 | Centre deck board |

1 | 1200 | 145 | 22 |

| 7 | Outer block |

6 | 145 | 100 | 78 |

| 8 | Central block |

3 | 145 | 145 | 78 |

All dimensions in millimetres, according to UIC 435 Codex. Blocks in EUR pallets can be made of either solid or particle wood.

EUR pallets have the following specific characteristics:

Strictly defined external dimensions as well as those of individual elements;

railway or EPAL oval logo on the left-hand block;

ha-numeric markings on the middle block with the following pattern - LLL-Y-MM (pallet manufacturer's licence number, Year, Month of pallet manufacture);

ISPM15 fitosanitary treatment sign (absolutely mandatory for all pallets manufactured since 01.01.2010)

control staple (mandatory for new pallets, as shown in the table)

repair nail for repaired pallets;

Sections of edges are cut off evenly across the entire height of the pallet

The moisture content of new EPAL pallets must not exceed 22%.

All EUR EPAL pallets manufactured since 01.01.2010 need to undergo ISPM15 fitosanitary heat treatment, confirmed by the IPPC marking . Since 01.01.2011 a requirement has been in place whereby such pallets need to be dried in kilns.

Copyright © 2024 JCG Pallet Manufacturer